Designed and manufactured in Great Britain from original designs, Spendor loudspeakers – which include the accessible A-Line and the enthusiast D-Line and Classic – deliver a transparent and musical sound that performs well above their price point. Indeed, so good are Spendor loudspeakers, the A4 floor-standers won a coveted five-star What Hi-Fi? Award earlier this year.

Creating a loudspeaker as good as a Spendor, particularly one that’s as aesthetically pleasing as it is sonically proficient, is no easy task. In the video below, each stage of the six-day build process has been beautifully documented, beginning with an initial concept that’s cleverly matched to the market need by the Spendor team.

The initial concept goes through research and development, a year-long process of experimentation to find the perfect sound for the product. Detailed drawings are made using modern CAD (computer-aided design) software, while the effects of different drivers, styles and materials are precisely calculated. At every stage of the process, the Spendor team takes comprehensive measurements and listens, listens and then listens to the loudspeaker again.

Every part of the loudspeaker has a profound effect on its sound. The cabinets, crafted with sophisticated multi-axis computer controlled machining, are assembled by skilled operators with decades of experience. The natural veneers that give the cabinets their smart, modern styling are matched from a variety of premium woods before going through a process of mirroring and laying to achieve the perfect look. The cabinet is then lacquered and polished with a meticulous attention to detail for a beautiful finish.

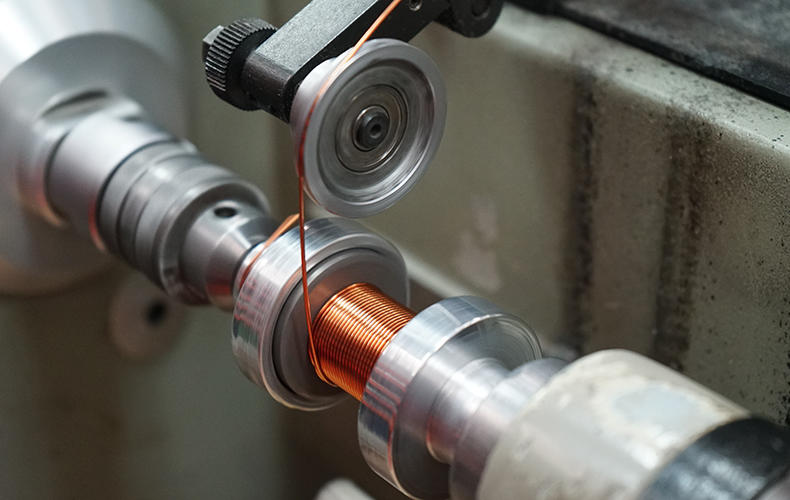

The heart of a loudspeaker is the drive unit. Spendor uses vacuum formed EP77 polymer cones mounted inside a die-cast magnesium alloy chassis. Aerospace-grade adhesives – as strong as steel – marry the high density ferrite magnet ring and Kevlar composite bass cones. It’s this precision alignment of cone, coil and suspension assembly – as well as premium crossovers made with precision inductor winding and gold plated four-layer circuit boards – that give Spendor speakers their sought-after sound.

The cabinets and drivers are brought together to create a fully working loudspeaker that – like at every stage of the process – is tested and calibrated against Spendor’s laboratory reference to ensure it meets the company’s meticulously high standards. Finally, the loudspeaker is packed and sent out to one very happy customer. A year of extensive design work is turned into a hand-built loudspeaker in six extremely labour-intensive days.

Such craftsmanship is why Spendor can create the innovative, elegantly engineered and beautiful sounding loudspeakers that have astonished listeners for over 40 years.